0 Ostukorvis

Since the year 2000 our company launched its own production of the spring blocks. Since 2004 spring blocks have been manufactured under the auspices of the well-known American concern Leggett & Platt, which is present in the markets of 78 countries. Spring production has received powerful development thanks to the modern foreign automatic equipment, high-class specialists and a special system of work organization.

In two years the capacity of the enterprise has increased three times, the production area has expanded. Specialists of our company have wide access to the best world technologies in this industry. Our designers, technologists, key production personnel, logistics and marketing specialists have been trained in the leading mattress manufacturing companies in Europe and the USA. One of the most important achievements is the acquisition of an exclusive license for the production of a unique spring block Hourglass, developed by the experts from Leggett & Platt.

In the shortest possible time the spring factory has turned into a large multinational company with technologies, that are in many ways unique for domestic enterprises. In 2006 spring production was again incorporated into “Ascona” and continues to develop nowadays. At the same time 20-25% of spring blocks today are bought from third-party organizations. The release of spring blocks "in a twist" is adjusted, which allows to optimize products transportation and storage.

Spring block is the basis of the mattress. Our technologists are constantly working on the development of the new modifications that can improve your sleep. This year, thanks to the modernization of production, it was possible to develop and manufacture new models of spring blocks, for example, original blocks for the Mediflex mattresses (including a mini-tunnel and a minipocket), as well as the pillow spring blocks.

Today, no company in Russia produces as many types of spring blocks as "Ascona" - any width, height and configuration of wire with a diameter of 0.8 to 2.4 mm. Any orders are accepted including limited orders, as well as orders on non-standard spring blocks. Today Ascona is the market leader in the spring block production.

The collections of mattresses, beds and accessories are constantly updated. The basis of the new collections of mattresses are the most modern scientific developments, on which Ascona specialists are foundning their work. The goal of our research is to make your sleep healthy and comfortable. All materials used by Ascona in their mattresses and sleep accessories are absolutely safe and comply with the highest standards, including fire safety. In mattresses and sleep accessories, Ascona uses time-tested materials, such as coconut slabs or sisal, as well as newer ones, such as viscolatex and gel. "Deep stitching" technology allows to make the mattress more comfortable. The Ascona factory is the largest production in Eastern Europe, with a total area of more than 40,000 m².

This year Ascona has mastered the release of spring mattresses in a twist, which makes the transportation much easier. The necessary technology for that type of pruduction, which is gluing together felt and coconut, except for us, in Eastern Europe does not possess any enterprise.

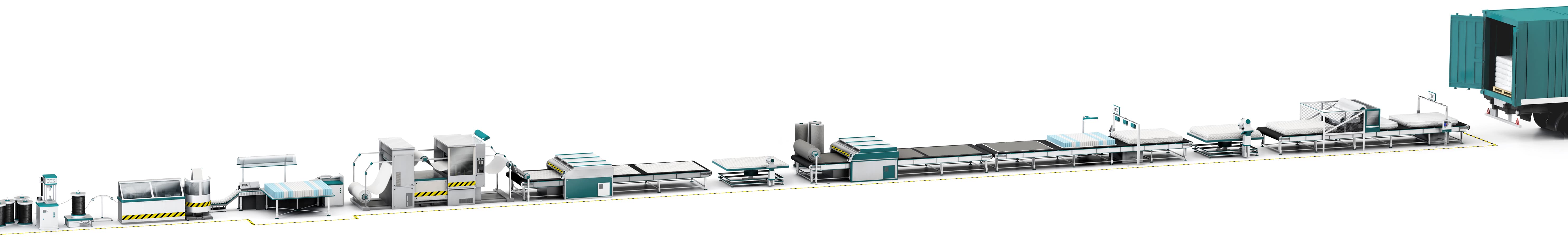

Most of the equipment, which Ascona is using in its production, is unique and has no analogues on the market. For example - an integrated 3-conveyor production system, an automatic production management system, planning and accounting of raw materials and finished products. Specialists Ascona have developed a new, non-standard sequence of the assembly of the mattress, which has significantly reduced the cost. The savings are directed to reducing the market price of the mattress.

In production of our mattresses the new automatic glue line is used. The machine applies molten glue granules exactly where it is needed. In addition, the new hot melt glue is odorless and completely harmless. New technology has improved the quality of products, as well as up-graded the work culture.

The specialists of Ascona have developed an improved sequence of assembling a mattress, which has significantly reduced the cost of the final product. Saved funds are used to reduce the market price. And the equipment with which is used in the production process is unique and has no analogues in Eastern Europe.

For 25 years we have been investing in innovation and technology development, studying new materials, introducing advanced technologies and finding original design solutions for creating comfortable mattresses for a good sleep.

Ascona mattresses are mattresses of consistently high quality. All materials and components of mattresses meet the highest requirements for the orthopedic products. Each new model or series that is being prepared for released at the mattress factory undergoes multiple tests. To maintain a high stable quality of products in the production of Ascona mattresses, a multistage quality control of raw materials and products has been organized, thanks to its own laboratory of the quality control of manufactured products.

In the production of Ascona mattresses only modern and high-quality environmentally friendly materials from leading world manufacturers are used, which meet all international safety quality standards.